Ürün Bilgisi

Oil type distribution transformers are transformers variable with input and output voltages in desired ratios up to 36 kV maximum voltage level and up to 5,000 kVA power, where cooling in transformers is provided by transformer oil.

Pruducts

- Solar Power Plant Transformer

- Wind Turbine Transformer

- Distribution Transformer

- Earthing Transformer

- Dual Voltage Transformer

- Rectifier Transformer

- Starting Transformer

- Autotrafo

- Shunt Reactor

- Series Reactor Limiting Short Circuit Current Multi Winding Transformer

All transformers are manufactured in conformity with ISO 9001 and ISO 14001. At the end of the production process, transformers are individually tested in accordance with IEC Standards.

Hermetic Transformers

25 – 5.000 kVA power range (transformer requests larger than 5.000 kVA should be evaluated on a project basis), up to 36 kV maximum voltage level, three or single phase, oil filled, naturally cooled (ONAN), with off-load or on-load tap changer, can be used both externally and internally, are produced in accordance with national / international standards and customer requests.

Hermetic oil type distribution transformers are manufactured in special vacuum chambers by adjusting the pressure in the factory environment in such a way that there is no air gap and no contact with the atmosphere. Therefore, since there is no moisture in the boiler, the deterioration in the oil caused by oxidation is minimized.

Since the oil in hermetic transformers does not come into contact with the atmosphere, it does not require oil change and maintenance in certain periods as in transformers with expansion tank. Hermetic oil type transformers can be used in smaller areas in terms of height compared to tank transformers.

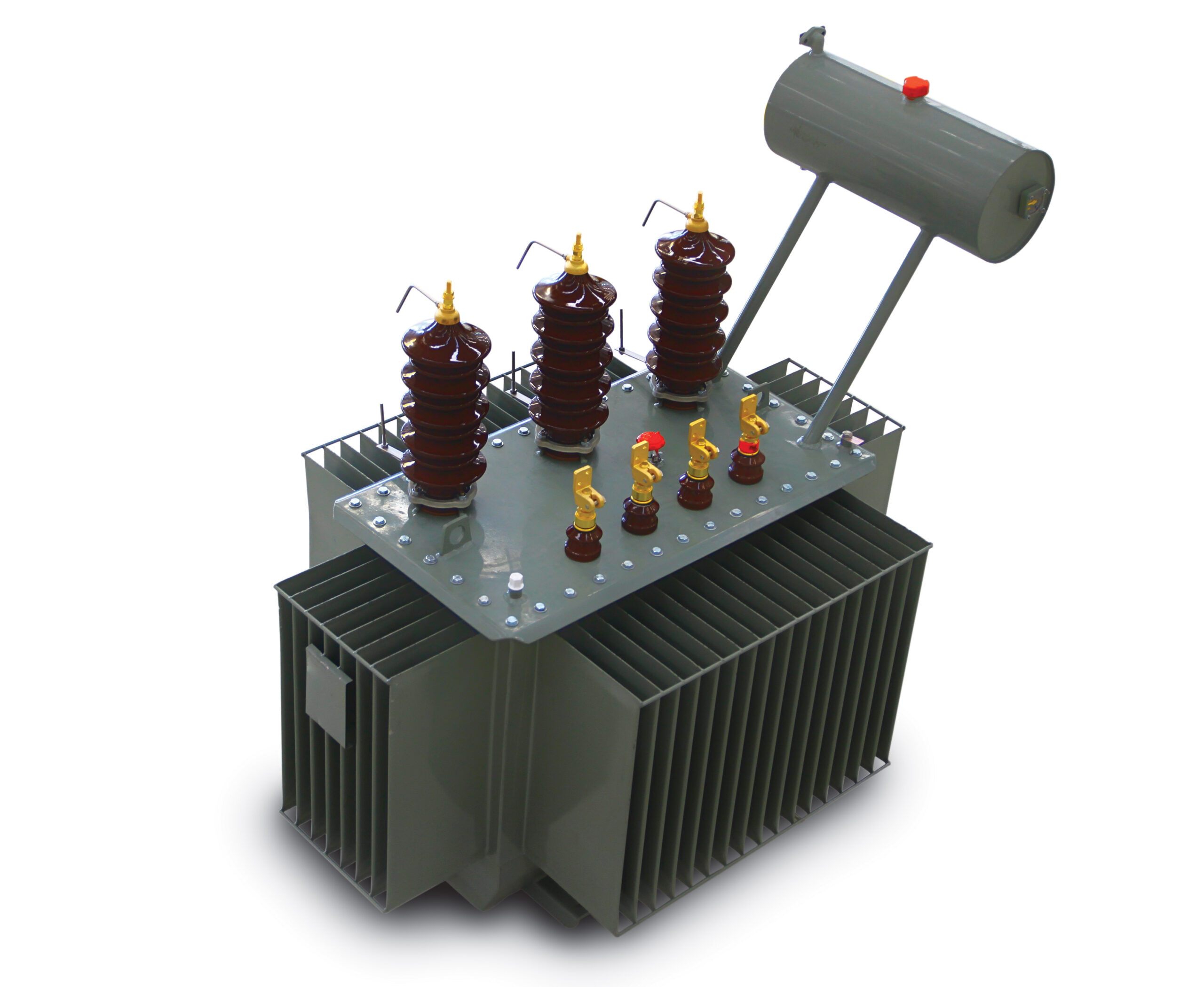

Transformers with Expansion Tank

Transformer with expansion tank; 25-5000 kVA power range (transformer requests larger than 5.000 kVA should be evaluated on project basis), up to 36 kV maximum voltage level, three or single phase, oil cooled, natural cooling (ONAN), with off-load or on-load tap changer, can be used externally and internally, are produced in accordance with national / international standards and customer requests.

Since the transformer with expansion tank is open to the atmosphere, the oil pressure changing due to thermal effects is dehumidified by the slicagel (air dryer) in the transformer’s tank and air exchange is provided.

In the expansion tank type transformers, due to temperature changes of ambient, silicagel loses its protection against humid inside oil by time and that cause problems for transformer oil. For this reason, maintenance such as measuring the breakdown voltage of oil and replacing the slicagel should be done by taking samples from the oil in certain periods.

Areas of Use

- Distribution Centers

- MV/LV Substations

- Construction sites

- Factories

- Industrial Zones

- Irrigation Projects

- Power Plants

- In-City Distribution Centers (Pole Type or Substation)

ACCESSORIES

1. Pressure Safety Valve

It is a preferred circuit element in hermetic designs. It protects the transformer tank in case of sudden pressure rise. It is mounted on the cover. If the tank is exposed to the internal pressure to which the valve is set, the valve opens and prevents the tank from rupturing by compensating the effect of the pressure through oil discharge. Optionally, it can be used with contact.

2. Hermetic Protection Relay

It is a relay used in hermetic transformers. The relay indicates gas discharge, oil temperature and internal pressure in the tank. It is generally used in transformers larger than 500 kVA. There are two contacts each for gas discharge, tank pressure and oil temperature on the relay. It gives alarm and trip warnings according to the set limit values.

3. Wheels

Wheels of various diameters, selected to be strong enough to carry the weight of the transformer, are shipped with the transformer depending on customer demand.

4. High Voltage Cable Box

It is a mechanical enclosure that protects transformer high voltage bushing connections against environmental influences. It can be designed in various IP classes depending on customer demand.

5. Low Voltage Cable Box

It is a mechanical enclosure that protects the transformer low voltage bushing connections against environmental influences. It can be designed in various IP classes depending on customer demand.

6. Switch Oil Temperature Thermometer

There is a maximum indicator showing the maximum temperature reached by the oil in the transformer and it can be reset with the button on the bottom. Oil temperature can be read up to 120°C. It is contacted. The electrical value of the micro switches can be set as 5A 250 VAC or 0.2 A, 250 VDC. If the customer wants to see the temperature reached by the oil in the transformer with the indicator on it without contact, Dial Type Thermometer should be used.

7. Buchholz Relay

It is connected with pipes between the transformer tank and the oil expansion tank. Buchholz relay is an element used to observe gas and oil movements in transformers. It warns of malfunctions that cause small gas accumulations in transformers, sudden oil fluctuations and oil leaks.

8. Magnetic Oil Level Indicator

It is the indicator used to check the oil level in the oil expansion tank. For changing the transformer oil, the oil level is indicated by a magnetically connected float. If desired, contact level indicators are also used.

9. The Dehydrating Breather

Yağ genleşme deposuna bağlantı olarak, yağ hacmi değiştiğinde, içinden geçen havada bulunan nemi bünyesinde hapsederek, yağa nem geçmesini önler. Nem alıcının büyüklüğü yağ miktarına bağlı olarak kullanılır.

Oil Bund (Optional)

Oil-type transformers contain transformer oil for cooling and insulation. These oils cause environmental pollution by mixing with soil and water in case of leakage.

Oil storage Tank should be used instead of concrete or pebbles where oil-type transformers are to be installed. The Oil storage Tank, which is used outdoors, provides safe drainage of rainwater with its special filters. It also minimizes the possibility of fire with different product ranges. Products are specially designed and manufactured in line with the demands of the customers in an environmentally and climate sensitive manner.

Medifor continues to design environmentally friendly products with the solutions it has developed.