Ürün Bilgisi

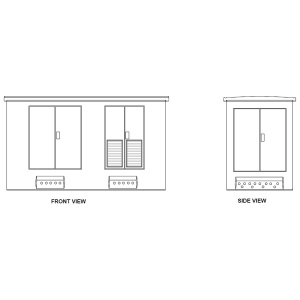

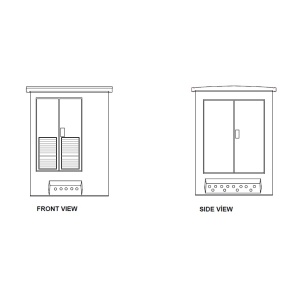

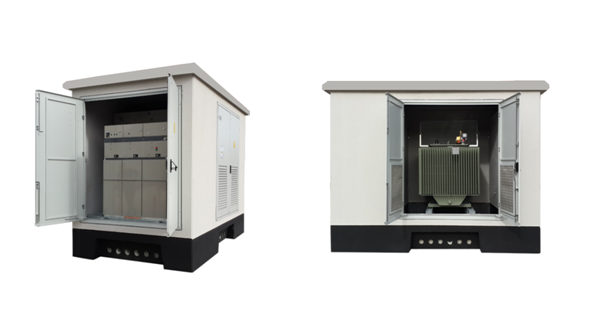

MV/LV Concrete Distribution and Transformer Centers are designed and manufactured according to the relevant specifications. Concrete Distribution and Transformer Centers consists three sections: HV switching units section, MV distribution transformer section, LV distribution panel section. Each section has independent doors and ventilation shutters.

Monoblock concrete substations and distribution centers are compact, environmentally friendly, aesthetic and reliable centers designed to isolate metal enclosed switchgears, transformers and LV panels from harsh environmental conditions. Monoblock concrete transformer and distribution centers, which do not require any additional assembly, are produced in accordance with all international standards and in different colors and sizes according to customer request, have also certified their reliability by internationally accredited laboratories.

Areas of Use

- Solar Power Plants (SPP), Wind Power Plants (WPP)

- Substations

- Industrial Plants

- Industrial Zones

- Water Pumping Stations

- Power Plants

- Medium Voltage Distribution Systems

- Generator Cabins

Advantages

- Very flexible division and door positions

- Low operating costs

- Long-term use

- Suitable for relocation

- Easy and Fast Assembly

- Environmentally compatible in structure and appearance

- Resistant to climatic conditions

- Customized design according to needs

Structural FeaturesConcrete Distribution and Transformer Centers consist of three main sections separated from each other.

- Low voltage distribution panel section

- Transformer section

- HV switching units section

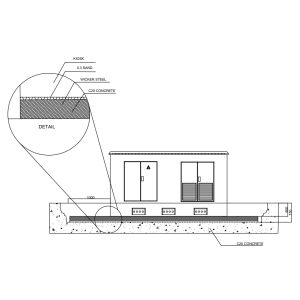

During producing concrete centers, IEC 60529 standard is taken into consideration in terms of access to energized sections and resistance to dust and water in moving sections. C35 quality concrete is used in concrete centers according to TS500 standard. Concrete centers are designed in a water-repellent structure. Ventilation panels on the walls of the center are manufactured in accordance with IP 23D protection degree.

Concrete Distribution and Transformer Centers can be safely transported by the lifting bars on the four corners. The sections are separated from each other by intermediate walls made of concrete.